Position:

Home > Product > PIG FARMING EQUIPMENT > Sow farrowing crate

Position:

Home > Product > PIG FARMING EQUIPMENT > Sow farrowing crate

Product Categories

Hot Products

Product Description

Automatic pig feeding systems Description

Automatic pig feeding systems

The automatic pig feeding systems consists of a feed tower, a feeding line, a power system, a control system, etc. The power box is started, the motor drives the feeding line to run in the pipeline, and the feeding line walks around each food tank in the interior of the house. Finally, return to the feed tower, and open a feed opening in the pipeline above each food tank. When the feed line drives the feed in the feed tower to run in the pipeline to the position of the feed port, the feed will be down the material. The pipeline goes down into the trough. There is a level sensor in the last trough. When the last trough is full, the level sensor will send the information to the control system. The control system will cut off the power and the power box will stop. The work process is completed.

The automatic pig feeding systems has been used for many years in many large-scale pig farms and has been approved by a large number of users. It not only saves a lot of labor, but also enables the pigs in the whole shed to eat at the same time, especially It is a sow. The feed line feeds the feed to the dosing cup. The dosing cup can be fed quantitatively according to the different physiological conditions of each pig, and the feed reaches each dose. After the start of the blanking system, the columns of the entire shed were unloaded at the same time, and the sow started to eat at the same time. This not only reduced the sow’s eager feeding mentality and screamed, but also the most accurate feeding, increasing the number of litters. Improve breeding efficiency.

Automatic pig feeding systems working process

Automatic pig feeding systems

Automatic pig feeding systems for swine farm/pig automatic feed line is the sensor automatically detects the material level in the chute. When the chute is short of material, under the control of the microprocessor, start the feed motor and the feed trough starts to feed. When the material in the chute is full, the sensor detects that the material is full, and the feeding motor stops feeding. The silo can hold 4000 kg of feed and is fed by the feeding material feeding silo. When the silo is short of material, the control box emits sound and light alarms, prompts the workers to feed, and when the silo is full, the control box has LED indications. Stop feeding. The automatic feeding system can realize full-automatic operation, reduce the labor intensity of the workers and increase the production efficiency of the farm.

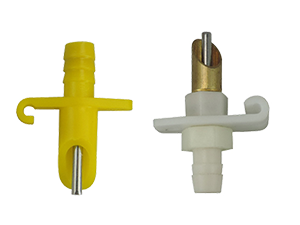

Automatic pig feeding systems compose: Feed Tower/Power Box/Automatic Feeding System/90 Degree Corner/Stainless Steel Chain, Nylon Scraper/Tubber Feeding Port/Sow Quantitative Cup.

Automatic pig feeding systems Maintenance:

Automatic pig feeding systems

1. The automatic feeding system is responsible for maintenance and operation by special personnel, and other personnel on the farm are not allowed to manipulate it to avoid accidents.

Product Parameters

| Name | Specification |

| Use | Pig, farrowing crates |

| Type | pig cage,galvanized farrowing stalls |

| Material | Hot dip galvanized steel pipe |

| Model Number | Hog Farrowing Stalls, 2.1*3.7m,2.1*3.6m |

| Size | Customized |

| Item | Animal Cages |

Related Products

Please fill in your procurement needs and contact information

Please fill in your procurement needs and contact information